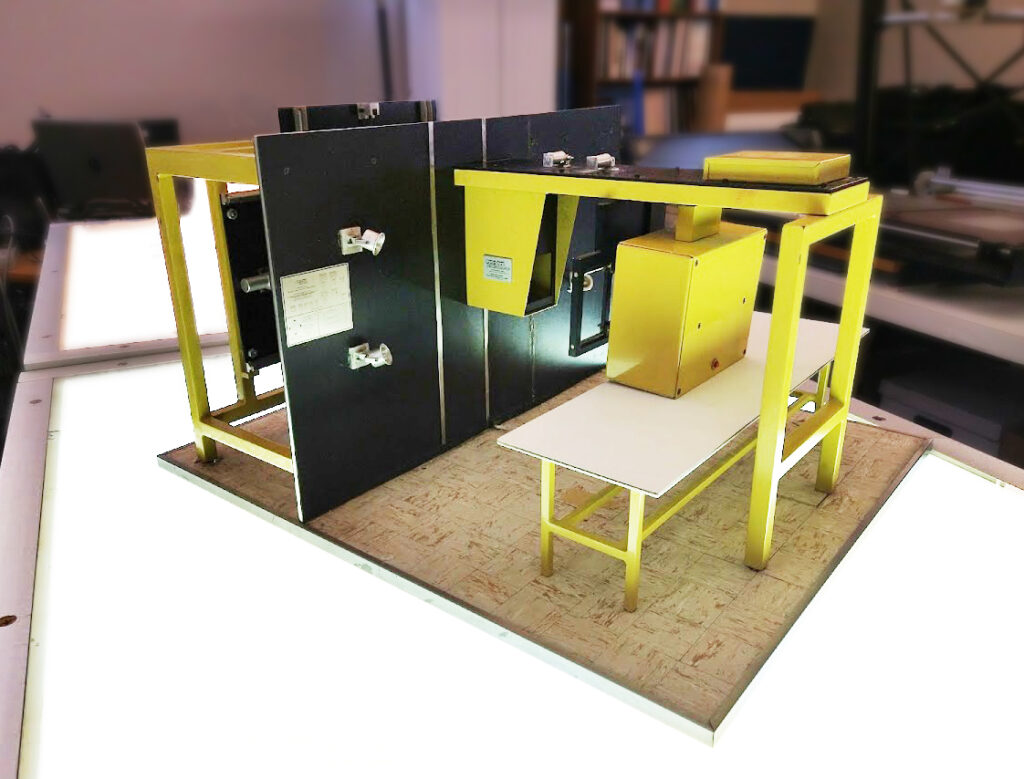

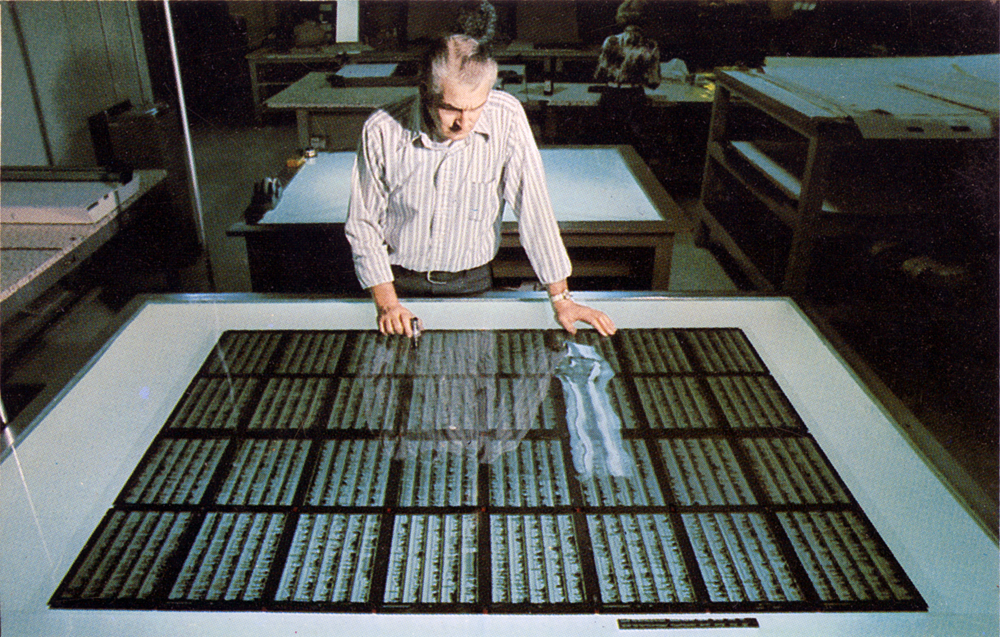

This is an 1/8-scale model of a revolutionary, step-and-repeat camera, that was built in Kansas City and sold all over the world- beginning in the United States and Canada, then England, Germany, Australia and Japan.

The company was owned by the Wally family who also owned the Western Blueprint Company in Kansas City. Jack Wally had worked as a photo-journalist for some years, and went to work for his father at Western Blue. While there, he started designing and selling his own reprographic cameras.

He eventually hit on the idea of a step-and-repeat camera for book and label printers. With his sons, he started a new manufacturing company in North KC called Opti-Copy. The company had a two major product lines, Litho– for the Graphic Arts market and Repro– for blueprints and engineering.

The Graphic Arts camera was named the Imposer. They called it that because, in book printing, pages on a large flat were printed in position so that the finished, printed sheet could be folded into a signature, and then trimmed and bound into a book. In the industry, the layout for correct placement of pages on a press sheet was called the imposition.

My dad, Ron Halsey, had been supervisor of the camera department at Kingsport Press in East Tennessee when they bought Opti’s first Imposer, S/N #001. (Kingsport had been, at one time, the largest book manufacturer in the world.) It wasn’t long till he went to work for them. Dad was the 6th person hired by Opti-Copy and in 1979, I became the 16th.

The systems were assembled in North KC and later at a new plant in Lenexa, KS. Opti was often visited by printers, film manufacturers and lens companies from all over the world. It seemed like someone visited every week to test a new film or light system. Opti was state-of-the-art, and enjoyed playing host to these companies as the collaborations were mutually beneficial. Once, forty of the largest publishers in Japan flew to Kansas City as a group to witness a demonstration.

The Opti-Copy Imposer could project pages or labels onto film flats, faster and more accurately than had ever been done, before. An 8- or 16-page flat could be produced in a couple of minutes. Press sheets of 100 labels could be set up and then run, automatically. The same jobs, when done by hand, were subject to human error and took much more time to accomplish.

After selling over 2,000 of the systems, in 1988, the Wally family sold the business to the Polychome Corp. and my Dad and I left the company. He wanted to start his own business, so with a partner, they founded ISI in Greensboro, NC. By that time, an Imposer system with all the “extras” cost around $250,000. Imaging Specialists bought, upgraded and operated 4 of these systems. We bought them, used (and for much less than a quarter of a million each!) By 1994 our family had bought out the partner.

The open-faced vacuum easel held large sheets of raw film on this- the darkroom side- of the camera.

We can now do, with modern systems and software, what would have once taken hours (or might even have been impossible) in the darkroom. But we continue to benefit from our experience and even some of our old Opti equipment.

A few years ago we traded Kingsport Press for the old Imposer #001. We are using its sliding copyboard (like the one on the model) in our photographic negative digitizing project.